Absolute and Continuous Position Measurement for Trolleys

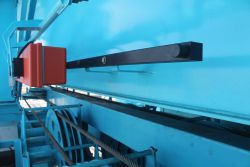

The Trolley RFM1.2 is an absolute and continuous measurement system based on transponder technology (RFID) and is especially designed for the highest possible level of Trolley positioning in a heavy duty environment with up to 2 mm accuracy.

The system uses a 134 kHz. programmable transponder, which is programmed with its exact position related to a chosen reference point. The transponder will be installed to the boom or girder of a crane and works battery-less. The system charges a transponder within its measurement range, reads out its code and determines the position of the transponder under the system.

The size of the antenna and having a transponder every 1 meter makes it possible to have continuous and absolute position measurement of your trolley position. Our sensor works together with an incremental encoder and processes and re-calibrates the encoder data every 50ms.

The system does not wear because it works contact less, is all weather proof and needs no regular maintenance. The antenna has a nominal reading distance of 90 but is capable to absorb significant play in reading distance and sideways.

Based on the same technology BTG is worldwide the leading company for position measurement of AGV’s in the automated Ports.